New aerospace vehicles continue to develop in the direction of high performance, long life, low cost, and good reliability, and the complex and integrated structure has become an urgent need. The application advantages of metal additive manufacturing technology in the aerospace field cover the design, cost, processing cycle, material utilization, and other aspects. It can be said that metal additive manufacturing technology is an important means for rapid and low-cost development and integration of modern aerospace parts to achieve rapid combination manufacturing.

The high-quality requirements of large-size aerospace components and the urgent production and delivery nodes often need to be both. Integrating more than ten years of experience in technology research and development, cooperative research and development, and engineering application, Platinum has developed a variety of technological manufacturing solutions for large-size parts of complex structures, high quality, combined manufacturing, and special materials.

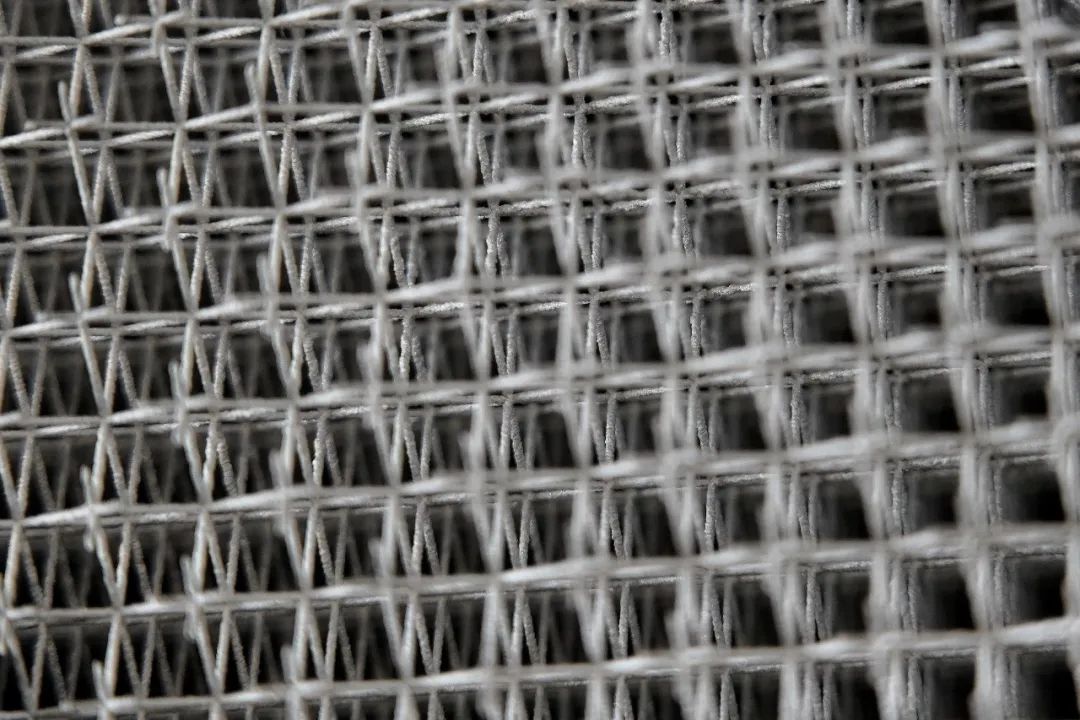

Selective laser melting forming technology (SLM) has high forming precision, which can realize the precision machining of complex structures and special material parts. Platinum's SLM equipment and related process and technology should develop with the potential, and constantly develop towards the direction of large size, high efficiency, intelligence, controllable quality, and stable performance.

The complex structure and subtle design make the sky parts more and more demanding for structural design. SLM technology for parts breakthrough outline and complexity constraints, from the source of aerospace manufacturing design, under the condition of satisfying parts performance and service conditions, realize functional priority design, make the metal parts to the direction of lightweight and integration, design lead and promote additive manufacturing technology breakthrough and development.

Laser stereotyping technology (LSF) can achieve rapid prototype manufacturing of direct manufacturing. In the past, large-size components mainly used the combination of forging and machining to manufacture parts, not only the production and processing cycle is long, but also the material utilization rate is very low. The LSF technology of Platinum has realized the near-net forming of large frame and beam load-bearing structure parts, which reduces the production cycle and cost of the parts, shortens the development cycle, and ensures the quality of the product. The overall performance of the parts meets the design requirements after testing.

Heeger Materials is a professional supplier of spherical metal powder and spherical HEA powder. We have supplied spherical powders for Boeing, AFIT, MIT, and many other universities around the whole world. Our spherical powders are of high quality and at the most competitive price. Welcome to send an inquiry to [email protected] to get a quote.