As industry advances, the demand for high-temperature-resistant materials has risen. High-temperature alloys (Nickel/Cobalt/Iron Based Master Alloys), a special type of metallic material, exhibit exceptional stability and mechanical strength at elevated temperatures. They find wide application across various industries. This article offers an overview of the performance characteristics and diverse industrial applications of high-temperature alloys.

Main performance characteristics include:

High-temperature resistance: High-temperature alloys can maintain good mechanical performance and structural stability in high-temperature environments, without melting, softening, or oxidation.

Excellent mechanical properties: High-temperature alloys have high strength, hardness, and toughness, allowing them to withstand complex mechanical loads at high temperatures and maintain structural stability and reliability.

Corrosion resistance: High-temperature alloys can resist corrosion in high-temperature, high-pressure, and harsh chemical environments. They have good corrosion resistance and are not easily affected by corrosion and oxidation.

Thermal expansion coefficient adaptability: High-temperature alloys have a low thermal expansion coefficient, reducing stress and deformation caused by thermal expansion at high temperatures.

Application Areas:

Aerospace industry: High-temperature alloys play a crucial role in the aerospace industry, being used in high-temperature components such as engine parts, turbine blades, combustion chambers, and propulsion systems. These alloys exhibit excellent resistance to high temperatures and corrosion, allowing them to withstand extreme conditions in high-temperature and high-pressure environments.

Energy industry: High-temperature alloys have significant applications in the energy industry. They are used to manufacture high-temperature components of energy devices such as gas turbines and steam turbines, including turbine blades and combustion chambers. The high-temperature stability and mechanical properties of high-temperature alloys effectively improve combustion efficiency and reduce energy loss.

Chemical industry: High-temperature alloys are commonly used in the chemical industry for manufacturing chemical equipment, reactors, heat exchangers, and pipelines. Their corrosion resistance allows them to operate stably in acidic and alkaline media, ensuring the safety and reliability of chemical equipment.

Automotive manufacturing industry: High-temperature alloys are also widely used in the automotive manufacturing industry. They are used to manufacture high-temperature components such as engine parts, turbochargers, and exhaust systems, to improve the performance and efficiency of automobiles.

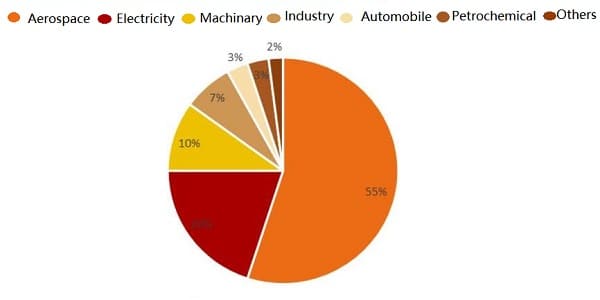

Percentage Distribution of Application Fields for High-Temperature Alloys

High-temperature alloys are vital in aerospace, energy, and chemical engineering, serving as a reliable material foundation for modern industry development. They propel advancements in related technologies. With ongoing scientific and technological progress, it's anticipated that high-temperature alloys will continue to enhance their performance and find even broader application prospects.

Heeger Materials is a reputable supplier offering top-notch Nickel/Cobalt/Iron Based Alloys products at competitive prices, which are widely used in interventional medicine. If you're interested, feel free to reach out to us at [email protected] for a quote, and we guarantee a response within 24 hours.