3D printing has brought economic benefits, but parts can still have flaws due to issues such as metal evaporation and thermal stress deformation. Traditional post-processing methods, including HIP, are necessary for directly printed parts, especially in industries like aerospace and healthcare that rely on titanium and nickel-based alloys.

Hot isostatic pressing (HIP) involves placing the product in a sealed container and subjecting it to equal pressure from all directions while applying high temperature. Under the influence of high temperature and pressure, the product undergoes sintering and densification. So, what does the HIP process bring about?

Densification to eliminate defects

At high temperatures, metals exhibit low strength and high ductility. Under the influence of external gas pressure, the metal in porous regions undergoes plastic deformation, causing the metals to come into contact and metallurgically bond with each other, resulting in the elimination of pores and achieving uniform densification throughout the material.

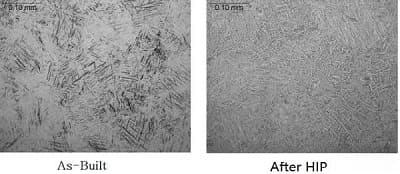

Improving organizational patterns

The hot isostatic pressing process, which involves high-temperature heating, is similar to annealing. It can eliminate the supercooled or metastable structures formed due to the fast cooling rate during the SLM process and transform them into high-temperature annealed structures.

After hot isostatic pressing (HIP), the fatigue limit strength of 3D printed Ti-6Al-4V alloy can reach 550 MPa (after 107 cycles), which is comparable to that of annealed and forged material. In addition, the anisotropy of fatigue performance is significantly improved.

Improving mechanical properties

Hot isostatic pressing (HIP) leads to significant changes in the mechanical properties of the material. Both SLM and EBM processes show a decrease in strength and an increase in plasticity after HIP, with a more pronounced effect observed in materials processed by SLM. The hardness of the material also decreases by approximately 5-10% after HIP. In general, HIP improves the toughness and resistance to fatigue crack propagation of the material.

Hot isostatic pressing (HIP) technology is commonly used for defect repair (such as pore fusion) of additive manufactured components, powder sintering, and diffusion bonding of various metals and alloys. It is particularly important in applications such as aerospace, medical, and marine industries to optimize material properties and enhance the lifespan of parts. Furthermore, a single HIP equipment can serve multiple printers, making it a cost-effective solution.

Although hot isostatic pressing (HIP) technology can eliminate internal defects in parts, its use still requires several conditions, and not all parts are suitable for it. The article only highlights the advantages of HIP. Relying on post-processing methods to address internal defects in metal printing is only one way, and the development of technology should also focus on internal process adjustments toward defect-free production.

Heeger Materials is a reputable supplier offering top-notch Spherical Powder and other 3D Printing Materials products at competitive prices, which are widely used in the 3D printing industries and science fields. If you're interested, feel free to reach out to us at [email protected] for a quote, and we guarantee a response within 24 hours.