A 3D printing solution for mass production of aluminum alloy adhesive has been developed, with the aim of improving efficiency and promoting widespread adoption of adhesive 3D printing technology.

The chosen aluminum alloy for this technology is the 6000 series (AlSiMg), which is known for its good ductility, strength, and dynamic properties. The resulting components exhibit high corrosion resistance, low density, and high mechanical strength.

Sintering Performance of 6000 Series Aluminum Alloys

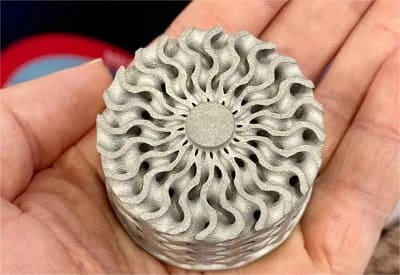

A 3D printing solution of aluminum alloy adhesive involves jetting adhesive into a powder bed to create solid components layer by layer. The final parts made with this process require sintering to fuse the particles into a solid component. 6000 series aluminum alloys are more susceptible to oxidation and less tolerant of impurities, making them one of the most difficult aluminum alloys to sinter, but they are also ideal for applications such as heat exchangers and lightweight structural components.

The 6000 series aluminum alloy materials have been developed to achieve sintered parts with a relative density exceeding 97%. X-ray computed tomography scans reveal no significant porosity, indicating high density and the microstructure exhibits sufficient densification.

Focus on Thermal Applications and Lightweight Component Manufacturing

The 6000 series aluminum alloy is known for its high tensile strength and thermal conductivity. After T6 heat treatment, the sample has a tensile strength of about 250 MPa and a thermal conductivity of 180 W/mK. This alloy is commonly used in heat exchangers and lightweight structural components.

Jetting adhesive 3D printing technology has made progress in the automotive, energy, electronics, and aerospace fields. It has successfully printed stainless steel, high-temperature alloys, aluminum, copper, and titanium, expanding its application possibilities.

Heeger Materials is a reputable supplier offering top-notch Spherical Aluminum Alloy powder and other Spherical Powder products at competitive prices, which are widely used in the 3D printing industry and science fields. If you're interested, feel free to reach out to us at [email protected] for a quote, and we guarantee a response within 24 hours.