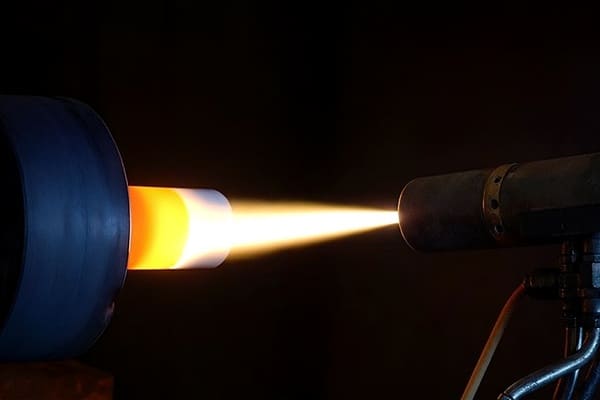

Thermal spraying, also known as thermal spray coating, is a versatile surface engineering process that has been widely adopted since the early 20th century. It involves heating feedstock materials (in powder, wire, or rod form) to a molten or semi-molten state and propelling them at high velocity onto a substrate to form a protective or functional coating. This technology enables the deposition of metals, ceramics, cermets, and polymers, providing enhanced properties such as wear resistance, corrosion protection, thermal barriers, and biocompatibility without significantly altering the substrate's bulk properties.

This guide explores the world of thermal spraying materials, offering a comprehensive overview of their primary types, intrinsic properties, and diverse applications across key industries such as aerospace, energy, and healthcare.

At Heeger Materials Inc., we specialize in high-quality thermal spray materials with various forms and specifications, ensuring optimal performance for industrial and scientific applications.

Importance of Thermal Spray Materials in Modern Industry

Thermal spray materials are far more than simple industrial consumables; they have become indispensable "performance enablers" for modern manufacturing. In an era that demands extreme equipment performance, extended service life, and sustainable development, these materials grant industrial components a second life—and even capabilities superior to their base material—through the magic of surface engineering.

Their critical importance can be summarized in three key areas:

1. Extending Lifespan and Enhancing Reliability:

Wear, corrosion, and high temperatures are the primary causes of industrial equipment failure. By spraying materials such as tungsten carbide, chromium oxide, or nickel-based alloys onto critical parts (e.g., jet engine blades, hydraulic pistons, and power boiler tubes), a robust "armor" is created, potentially increasing component lifespan several times. This dramatically reduces unplanned downtime and ensures the continuous, stable operation of production lines, forming the bedrock of industrial reliability.

2. Enabling Specialized Functions and Breaking Design Barriers:

Thermal spray materials make "functional surfaces" a reality. They can impart properties that the base material lacks, such as:

- Thermal Barrier Function: Yttria-Stabilized Zirconia (YSZ) coatings on jet engines and gas turbines allow turbines to operate at temperatures far exceeding the melting point of the underlying metal, significantly boosting efficiency.

- Biocompatibility: Hydroxyapatite (HA) or titanium coatings on artificial joints promote bone growth and integration, a critical technology in the biomedical field.

- Controlled Conductivity/Resistivity: They can be used to create conductive electrodes or insulating layers, finding applications in the semiconductor and electronics industries.

3. Driving Sustainable Manufacturing and the Circular Economy:

Often, a high-value core component (e.g., a crankshaft, turbine rotor) is scrapped due only to surface damage. Thermal spraying technology allows for the repair and remanufacturing of these valuable parts, restoring—and often enhancing—their original dimensions and performance. This not only saves 70-90% of the cost of a new part but also significantly reduces energy consumption and raw material waste, making it a cornerstone of green manufacturing and the circular economy.

Classification of Thermal Spray Processes

Thermal spray processes vary by heat source, particle velocity, and atmosphere, each suited to specific materials and applications.

Process | Heat Source | Particle Velocity (m/s) | Typical Temperature (°C) | Key Advantages | Common Applications |

Flame Spraying | Oxy-fuel combustion | 50-100 | 3000-3500 | Low cost, portable | Corrosion protection (Zn/Al) |

Arc Spraying | Electric arc | 150-300 | 4000-6000 | High deposition rate | Anti-corrosion on structures |

Plasma Spraying (APS/VPS) | Plasma arc | 300-800 | 10,000-15,000 | High melting point materials | TBCs in turbines |

HVOF/HVAF | Supersonic combustion | 500-1200 | 2500-3500 | Dense, low porosity | Wear-resistant carbides |

Cold Spray | Kinetic energy (no melting) | 500-1200 | <1000 (solid state) | No oxidation, repairs sensitive parts | Structural repairs (Al, Cu) |

Classification of Thermal Spray Materials

Thermal spray materials can be classified in various ways, but the most fundamental and universal method is based on their chemical composition and material properties. This classification directly correlates to the final coating performance and application. They are primarily categorized into four groups: Metals & Alloys, Ceramics, Carbides & Cermets, and Polymers.

1. Metals and Alloys

This is the most basic and widely used category, primarily for corrosion resistance, wear resistance, and as bond coats.

Pure Metals: Such as zinc and aluminum. Used primarily for cathodic protection (anti-corrosion) in atmospheric environments, e.g., for bridges and steel structures.

Alloys:

- Nickel-Based Alloys: e.g., Nickel-Chromium (NiCr). It offers excellent resistance to high-temperature oxidation and hot corrosion, commonly used in boiler tubes and gas turbines.

- Cobalt-Based Alloys: e.g., Stellite alloys. Possess outstanding wear resistance and red-hardness (ability to retain hardness at high temperatures), used for valve seats and turbine blade edges.

- Iron-Based Alloys: e.g., Stainless steels. Cost-effective solutions for general wear, corrosion protection, and component repair.

Bond Coat Materials: Such as Molybdenum (Mo) and Nickel-Aluminum (NiAl, Ni5Al) composite powders. They adhere strongly to the substrate and form a rough oxide surface, providing an ideal "anchor" for subsequent top coats.

2. Ceramics

Ceramic coatings primarily provide excellent high-temperature resistance, thermal insulation, wear resistance, and electrical insulation.

Oxide Ceramics:

- Alumina (Al₂O₃): High hardness, excellent wear resistance, and electrical insulation. Widely used in pump seals and insulating components.

- Chromia (Cr₂O₃): Dense, hard, and offers superior corrosion-erosion resistance. Often used for hydraulic rods and textile machinery parts.

- Zirconia (ZrO₂): When stabilized with Yttria (Y₂O₃), it becomes the premier Thermal Barrier Coating (TBC) material due to its very low thermal conductivity, extensively used in hot-section components of jet engines and gas turbines.

Non-Oxide Ceramics: Such as Chromium Carbide (Cr₃C₂), often used in a metallic matrix (like NiCr), providing excellent wear and corrosion resistance at high temperatures (540°C-900°C).

3. Carbides & Cermets

This category combines the high hardness of ceramics with the toughness of metals, making them key materials for combating severe wear.

- Tungsten Carbide (WC): This is the most important wear-resistant coating material. To prevent decomposition during spraying, WC grains are typically embedded in a metallic binder phase like Cobalt (Co) or Nickel-Chromium (NiCr), forming WC-Co or WC-NiCr composite powders. The coatings exhibit extreme hardness and good toughness, used extensively in aerospace, mining, and the oil & gas industry.

- Chromium Carbide (Cr₃C₂): As mentioned, typically used with a NiCr matrix for high-temperature wear applications.

- Cermets: A term specifically for composites of carbides (the "ceramic") in a metallic ("metal") binder.

4. Polymers

Polymer coatings are primarily used for chemical corrosion resistance, anti-fouling, and electrical insulation, typically applied at lower temperatures.

- Common Materials: Include epoxy, nylon, and polyethylene. They are often applied as powders via flame spray techniques for lining chemical tanks, pipe internals, and in the food processing industry.

Looking for high-quality thermal spray materials? Explore Heeger Materials’ Selection.

Thermal Spray Materials, Properties and Selection Criteria

Selecting the appropriate coating material is a systematic engineering task that requires a comprehensive consideration of coating properties, process feasibility, and overall cost-effectiveness. Understanding the core properties of materials is the foundation for making the right choice.

1. Mechanical Properties

- Hardness: Typically measured as microhardness (HV), it is a key indicator of a coating's resistance to wear. Generally, higher hardness correlates with better abrasion resistance (e.g., Tungsten Carbide, Alumina).

- Bond Strength: The adhesive strength between the coating and the substrate is fundamental to preventing spallation and ensuring long-term reliability. Insufficient bond strength leads to premature failure.

- Toughness/Brittleness: The coating's ability to withstand impact or stress without cracking. Hard ceramic coatings are often brittle, while metallic coatings are more ductile.

2. Physical & Chemical Properties

Wear Resistance: The ability to resist material loss due to friction, erosion, or abrasion. This is one of the primary functions of thermal spray coatings.

Corrosion Resistance: The ability to resist electrochemical or chemical attack. The material must be selected based on the specific environment (e.g., atmosphere, seawater, acid, alkali). Examples include Zinc, Stainless Steel, Nickel alloys, and Chromia.

High-Temperature Performance:

- Oxidation Resistance: Resistance to reaction with oxygen at high temperatures.

- Hot Corrosion Resistance: Resistance to attack from molten salts (e.g., sulfates, vanadates) at high temperatures.

- Thermal Barrier Property: Low thermal conductivity to insulate the underlying metal substrate (e.g., Yttria-Stabilized Zirconia).

- Thermal/Electrical Conductivity: Depending on the application, coatings can serve as thermal barriers, heat sinks (e.g., Copper), or conductive/insulative layers.

Porosity: The volume percentage of pores within the coating. Corrosion-resistant coatings require low porosity to block corrosive media, while certain bio-coatings or oil-retaining bearings require controlled porosity.

3. Process-Related Properties

- Thermal Expansion Match: The coefficient of thermal expansion (CTE) of the coating and substrate should be as close as possible. A significant mismatch generates high thermal stresses during cooling or thermal cycling, leading to cracking or spallation.

- Phase Stability: The material should remain chemically and structurally stable during the high-temperature spray process and in service, avoiding detrimental phase transformations that degrade performance.

4. Major Spray Processes and Their Typical Material Matches

The table below clearly illustrates the typical matching relationships between mainstream processes and materials:

Spray Process | Heat Source Temp. (Approx.) | Typical Material Matches | Rationale & Coating Characteristics |

Flame Spray | 3,000 °C | Metal Wires (Zn, Al, Cu-alloys), Ceramic Rods (Alumina), some powders | Low-cost, simple equipment. However, coatings have lower bond strength and higher porosity. Used for corrosion protection, dimensional restoration in non-critical applications. |

Arc Spray | 5,000 °C | Metal & Alloy Wires (Zn, Al, Stainless Steels, Ni-alloys, High-Carbon Steel) | Extremely high deposition efficiency, very low cost. Bond strength is higher than flame spray. The most cost-effective solution for large steel structure corrosion protection and wear part repair. |

HVOF | 3,000 °C | Tungsten Carbides (WC-Co/CoCr), Chromium Carbides (Cr₃C₂-NiCr), Metal Alloys | Very high flame velocity (supersonic), high particle kinetic energy. Coatings are extremely dense with high bond strength and low oxide content. The preferred process for high-performance wear-resistant and corrosion-resistant coatings. |

Atmospheric Plasma Spray (APS) | 15,000 °C | Virtually all materials, especially high-melting-point ceramics (Alumina, Chromia, YSZ), Cermets | Plasma arc temperature is extremely high, capable of melting any material. Offers the greatest flexibility. The primary process for ceramic coatings, functional coatings (e.g., TBCs-YSZ), and R&D. |

Vacuum Plasma Spray (VPS) | 15,000 °C | Reactive Metals (Ti, Ta), MCrAlY Bond Coats | Process occurs in a vacuum or low-pressure inert atmosphere, resulting in almost no oxidation. Used to produce very pure, oxide-free high-performance coatings, primarily for critical aero-engine components. |

For powder materials, considering the powder feeding characteristics and economic factors, their particle size generally falls within a certain particle size distribution range. Typically, the particle size range for metal powders is from -150 mesh to +270 mesh, while ceramic powders are commonly in the range of -325 mesh to +400 mesh. In addition, different processing methods also impose specific requirements on the powder particle size. For example, powders used in high-performance supersonic plasma spraying should typically range from -325 mesh to +400 mesh.

Explore our optimized thermal spray materials.

Future Trends

New Materials

- Nanostructured coatings: 25-35% higher hardness and lifespan.

- High-entropy alloys (HEAs): FeCoNiCrMn, AlCoCrFeNi—superior oxidation and wear; cold spray deposition is advancing rapidly.

- Amorphous coatings and eco-friendly Cr-free alternatives.

Advanced Technologies

- Solution Precursor Plasma Spraying (SPPS): Finer microstructures for next-gen TBCs.

- Supersonic Laser Deposition and expanded cold spray for structural repairs/additive manufacturing.

Digitization and Intelligence

- Real-time monitoring with AI optimizes parameters; machine learning predicts coating performance, reducing development time by 25%.

Sustainable Thermal Spraying

- Powder recycling rates target 40% by 2026, and low-energy cold spray and closed-loop systems reduce waste by 30%.

Request a custom quote for high-quality thermal spray materials.

Conclusion

The continuous evolution of thermal spraying materials and processes is consistently pushing the boundaries of industrial manufacturing, providing critical support for equipment longevity, performance enhancement, and sustainable development. From traditional wear and corrosion resistance to cutting-edge applications like thermal barrier coatings, biomedical implants, and additive manufacturing, thermal spraying has matured from a surface repair technique into a core driver of innovation across multiple industries.

Whether safeguarding jet engines in the skies or extending the service life of critical industrial assets, thermal spraying materials will continue to serve as the "art of surface engineering," silently shaping a more reliable, greener, and more capable industrial future from behind the scenes.

For top-quality thermal spray materials, Heeger Materials provides tailored solutions for various applications.

Looking for premium thermal spray materials? Contact us today!