Rare earth elements are extremely important strategic resources that play an irreplaceable role in industrial production. They are essential in various applications such as automotive glass, nuclear magnetic resonance, optical fibers, liquid crystal displays, etc. One of these rare earth metals is yttrium (Y), a grayish metal. Due to its relatively abundant presence in the Earth's crust, yttrium is relatively inexpensive and widely used in its alloy and oxide forms.

Yttrium Oxide (Y2O3) is the most important yttrium compound. It is insoluble in water and alkalis, but soluble in acids. Yttrium oxide appears as a white crystalline powder with a cubic crystal structure. It possesses excellent chemical stability, low volatility under vacuum, high heat resistance, corrosion resistance, high dielectric constant, and transparency to infrared radiation. As a result, it finds applications in various fields.

Yttrium-stabilized zirconia powder synthesis:

When pure ZrO2 cools, it undergoes phase transformations from cubic to tetragonal to monoclinic, with the t→m phase transition causing a volume expansion of about 5%. If the t→m phase transition is stabilized at room temperature and induced by stress during loading, the material can absorb a significant amount of fracture energy due to the volume effect. This leads to exceptional fracture toughness and wear resistance, known as phase transformation toughening.

A stabilizer must be added to stabilize the high-temperature tetragonal phase at room temperature under specific sintering conditions to achieve phase transformation toughening in zirconia. Y2O3 is the most extensively researched stabilizer, leading to excellent mechanical properties, high strength, and good fracture toughness in the sintered Y-TZP material. The material also exhibits fine and uniform grain sizes, making it highly noteworthy.

Sintering aid:

Sintering aids are often required for the sintering of many special ceramics. They typically form a solid solution with the material, prevent crystal phase transitions, inhibit grain growth, or generate a liquid phase. For example, for alumina sintering, MgO is added to refine the grain size and suppress discontinuous grain growth. Usually, Y2O3 is mixed with MgO to achieve better results.

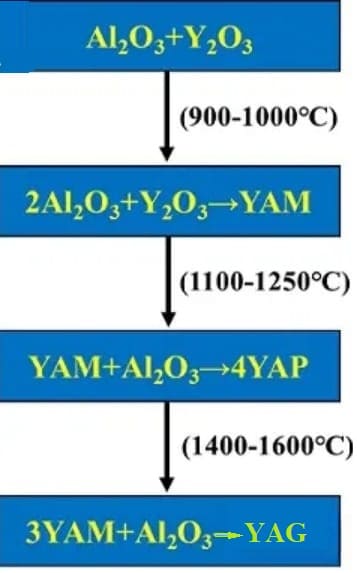

YAG powder synthesis:

YAG (Yttrium Aluminum Garnet) is a synthetic compound with a high melting point and hardness. It is colorless and insoluble in various acids. YAG powder is traditionally synthesized through high-temperature solid-state reactions between yttrium oxide and aluminum oxide, resulting in the formation of YAG crystals.

YAG is widely used for its ability to match the higher vacuum energy of fluorescent materials and maintain optical stability under high electron impact. It can be doped with trivalent rare earth ions, such as Ce3+ and Eu3+, to significantly improve luminescent properties. YAG crystals are transparent, physically and chemically stable, and have high mechanical strength and resistance to thermal creep, making them ideal for use as laser crystal materials.

Transparent Ceramics:

Yttrium oxide is a key material in the field of transparent ceramics. It has a cubic crystal structure and exhibits isotropic optical properties. Compared to light-transmitting alumina, it offers reduced image distortion, making it valuable for high-end lenses and military optical windows. The main characteristics of its physical and chemical properties are:

High melting point, good chemical and photochemical stability, wide optical transparency range (0.23~8.0μm)

At 1050 nm, its refractive index is as high as 1.89, giving it a theoretical transmittance of more than 80%.

Y2O3 has a wide band gap that can accommodate the emission energy levels of trivalent rare earth ions, allowing for tailored luminescence performance through doping. This enables its multifunctional application.

Y2O3 has a low phonon energy with a maximum cutoff frequency of around 550 cm–1. This low phonon energy reduces the likelihood of non-radiative transitions and enhances the probability of radiative transitions, resulting in improved luminescence quantum efficiency.

Thermal conductivity is high, about 13.6 W/(m·K). High thermal conductivity is extremely important for it as a solid laser medium material.

Due to its excellent physical and chemical properties, Y2O3 transparent ceramics are widely used and potentially developed, mainly including infrared windows and dome covers of missiles, visible and infrared lenses, high-pressure gas discharge lamps, ceramic scintillators, ceramic lasers, and other fields.

Yttrium oxide is a versatile compound used in electronics, materials science, energy, medicine, and biotechnology, making significant contributions to innovation and progress in different fields as technology advances.

Heeger Materials is a reputable supplier offering top-notch Rear Earth Materials products at competitive prices, which are widely used in science and research. If you're interested, feel free to reach out to us at [email protected] for a quote, and we guarantee a response within 24 hours.