Rare earth permanent magnets are made by combining rare earth elements Neodymium (Nd), Samarium (Sm), or Terbium (Tb) with transition metals (Fe, Co, B) through powder metallurgy techniques. The mixture is pressed, sintered, and magnetized to create highly magnetic materials.

Rare earth magnets, with their high coercivity and energy product, are vital in high-tech industries for efficient and lightweight magnetic devices, making them indispensable in modern industry.

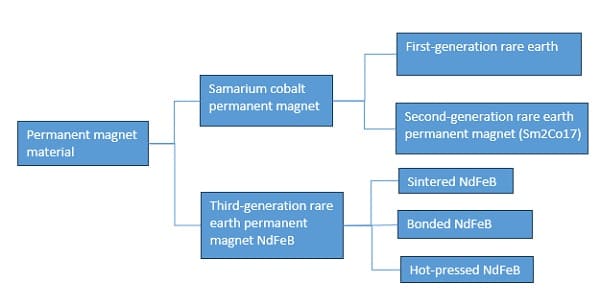

Rare earth magnets are divided into three generations: first-gen (SmCo5), second-gen (Sm2Co17), and third-gen (Nd2Fe14B). NdFeB magnets, the third-gen neodymium iron boron magnets, have better magnetic properties and lower production costs than samarium cobalt magnets. Consequently, NdFeB magnets have largely replaced the first and second-gen magnets and are now the most widely used rare earth magnets.

NdFeB Permanent Magnets are advanced rare earth permanent magnets widely used in various industries. They have a composition of neodymium, praseodymium, iron, and boron. NdFeB magnets offer high energy density, coercivity, and strong magnetic and mechanical properties. However, they have poor resistance to high temperatures and are susceptible to powdering and corrosion.

NdFeB Permanent Magnets Types

NdFeB Permanent Magnets materials can be classified into sintered, bonded, and hot-pressed types. The table below compares these categories.

Specifications | Sintered NdFeB: | Bonded NdFeB: | Hot-pressed NdFeB: |

Intrinsic coercivity (Ke) | 11-40 | 7-8 | 10-25 |

Maximum energy product (MGOe) | 33-58 | 8-12 | 15-42 |

Remanence (EGs) | 11-15 | 6-8 | 12-14 |

Maximum operating Temperature (℃) | 250 | 150 | 200 |

Production process | Using the powder metallurgy process, the alloy obtained after melting is made into powder and pressed into a green compact in a magnetic field. The green compact is then sintered and formed in an inert gas or vacuum environment. | It is a magnetically plasticized granular material made by mixing a binder with neodymium iron boron (NdFeB) magnetic powder and then formed using a plasticity material molding process. | It is primarily produced through hot extrusion and hot deformation processes. |

Characteristics | High magnetic performance, high coercivity, and high operating temperature. It is currently the most produced and widely used rare earth permanent magnetic material. | It has relatively weak magnetic performance and mechanical strength, but it has a simple process, low cost, small size, high precision, and a uniform and stable magnetic field. | It has advantages such as high magnetic properties, high density, high orientation, good corrosion resistance, high coercivity, and near-net shaping. However, it has high production costs, poor mechanical properties, and relatively low overall output. |

Application areas | Automotive industry, industrial motors, consumer electronics, clean energy, aerospace, and other fields. | In the fields of office automation equipment, electrical machinery, audiovisual equipment, instrumentation, small motors, etc. | It is mainly used in the automotive EPS motor field. |

NdFeB Permanent Magnets Applications

- Electronics: They are used in motors, sensors, speakers, and disk drives, providing strong magnetic force and high energy conversion in electronic devices like mobile phones.

- Green energy: NdFeB magnets are essential for wind power generation and electric vehicles, improving energy conversion efficiency and system performance.

- Medical equipment: They play a crucial role in MRI devices, providing stable magnetic fields and high-resolution imaging.

- Power industry: NdFeB magnets are used in generators, motors, and transmission systems, ensuring high energy conversion and stability.

NdFeB magnets have revolutionized technology and green energy. They offer strong magnetism, efficient energy conversion, and enhanced system performance. As technology progresses, we can expect NdFeB magnets to be used in more fields, creating a smarter and greener future for humanity.

Heeger Materials is a reputable supplier offering top-notch Rear Earth Materials products at competitive prices, which are widely used in science and research. If you're interested, feel free to reach out to us at [email protected] for a quote, and we guarantee a response within 24 hours.