Viewed products

-

Customized...

Customized High-Entropy Alloy...

-

Boron Carbide Powder,...

Boron Carbide (B4C) Powder is a black...

High-entropy Alloy Powder

- Products

- Deposition Materials

- Refractory Metals

- Rare Earth Materials

- Powder

- Technical Ceramics

- Lanthanum Hexaboride (LaB6) Materials

- Pyrolytic Boron Nitride (PBN) Products

- Boron Nitride (BN) Products

- Alumina Ceramics (Al2O3)

- Aluminum Nitride (AlN) Products

- Silicon NItride (Si3N4) Ceramics

- Silicon Carbide (SiC) Ceramics

- Graphite Products

- Zirconia Ceramic

- MAX Phase Ceramic Materials

- Boron Carbide Ceramics (B4C)

- Magnesium Oxide Ceramics (MgO)

- Quartz Ceramics

- Macor Machinable Glass Ceramic

- Beryllium Oxide (BeO) Ceramics

- Piezoelectric Ceramics

- High Purity Materials

- Precious Metals

- Chemicals

- Crystals & Substrates

- Applications

- Other

View larger

View larger Customized High-Entropy Alloy Spherical Powder

HM3190

New product

Customized High-Entropy Alloy Spherical Powder is manufactured using advanced atomization technology, featuring perfect sphericity, extremely low oxygen content, and a narrow particle size distribution. Heeger Materials is a professional supplier and manufacturer of high-quality High-Entropy Alloy Spherical Powder, offering customized solutions for compositions and particle sizes.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Shape | Spherical Powder |

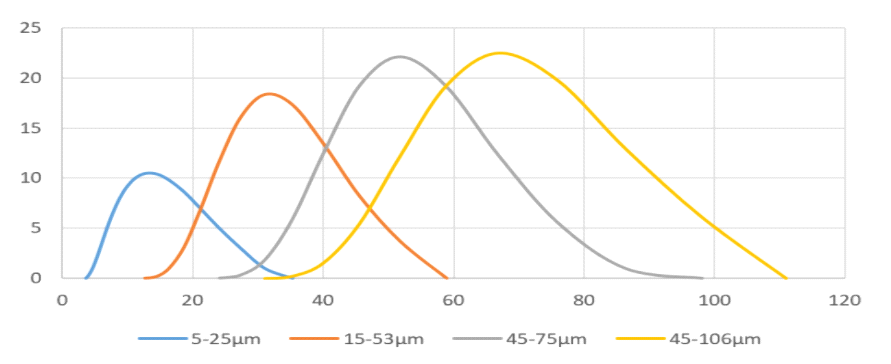

| Particle Size | 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, customized |

| Materials | High-Entropy Alloy, HEA |

More info

Customized High-Entropy Alloy Spherical Powder will be securely packaged in sturdy containers with cushioning materials to prevent movement or damage during shipping. This careful packaging ensures the product arrives in perfect condition, maintaining its high-quality standards throughout delivery.

Where to Buy Customized High-Entropy Alloy Spherical Powder in Bulk?

Heeger Materials Inc., a professional supplier and manufacturer of high-quality Spherical Powder products including Customized High-Entropy Alloy Spherical Powder, leverages extensive expertise in supply and export to offer competitive prices. We provide customized solutions to meet specific requirements, ensuring exceptional quality and customer satisfaction.

Heeger Materials Inc. was established in 2016 in Colorado, USA. We specialize in premium-grade metals, alloys, ceramics, powders, and other materials catering to research, development, and large-scale industrial production in scientific and industrial sectors.

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy