Viewed products

-

Nitinol Muscle Wire,...

Nitinol Muscle Wire, also called...

Titanium

- Products

- Deposition Materials

- Refractory Metals

- Rare Earth Materials

- Powder

- Technical Ceramics

- Lanthanum Hexaboride (LaB6) Materials

- Pyrolytic Boron Nitride (PBN) Products

- Boron Nitride (BN) Products

- Alumina Ceramics (Al2O3)

- Aluminum Nitride (AlN) Products

- Silicon NItride (Si3N4) Ceramics

- Silicon Carbide (SiC) Ceramics

- Graphite Products

- Zirconia Ceramic

- MAX Phase Ceramic Materials

- Boron Carbide Ceramics (B4C)

- Magnesium Oxide Ceramics (MgO)

- Quartz Ceramics

- Macor Machinable Glass Ceramic

- Beryllium Oxide (BeO) Ceramics

- Piezoelectric Ceramics

- High Purity Materials

- Precious Metals

- Chemicals

- Crystals & Substrates

- Applications

- Other

Nitinol Muscle Wire, Shape-Memory Wire

New product

Nitinol Muscle Wire, also called Nitinol actuator wire or shape-memory alloy wire, is made from NiTi shape memory alloy. It exhibits a recovery effect of at least 2% in a two-way memory cycle or 6% in a one-way memory cycle. Heeger Materials is a professional supplier and manufacturer of high-quality nitinol wire, offering customized solutions and competitive prices.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Diameter | 0.05-0.5 mm, or customized |

| Density | 6.5 g/cm3 |

| Materials | NiTi Alloy |

| Melting Piont | 1310 ℃ |

More info

Nitinol Muscle Wire, also known as electrically activated titanium or muscle wire, is made from NiTi shape memory alloy. It exhibits a recovery effect of at least 2% in a two-way memory cycle or 6% in a one-way memory cycle, and can perform work through electrical heating. When a current is applied, the alloy undergoes a phase change, causing it to contract and generating a driving force. By controlling the current and duration, the contraction speed can be adjusted. Available in a range of sizes and grades, HM's Nitinol Wire meets the highest standards of quality and reliability for demanding applications.

Nitinol Muscle Wire Chemical Analysis

Chemical Composition (wt%) | ||||

Fe | Ni | Cr | Cu | Nb |

≤0.05 | 54.5-57.0 | ≤0.01 | ≤0.01 | ≤0.025 |

C | Ti | Co | N+O | H |

≤0.05 | Balanced | ≤0.05 | ≤0.050 | ≤0.005 |

Nitinol Muscle Wire Dimensions and Tolerances

Dimension and Tolerances | ||

Wire Diameter (mm) | 0.10~0.30 | 0.30~0.50 |

Tolerances (mm) | ±0.005 | ±0.01 |

Nitinol Muscle Wire Technical Data

Type | Diameter | Resistivity | Recommended Load | Recommended Driving Current [A] | Recommended Duration of Energization [s] | Recommended Strain |

SMA01 | 0.1 | 3.2 | ≤1.3 | 0.35 | ≤0.4 | ≤3.5 |

SMA15 | 0.15 | 1.4 | ≤3.0 | 0.75 | ≤0.5 | ≤3.5 |

SMA18 | 0.18 | 1.14 | ≤4.3 | 0.90 | ≤0.5 | ≤3.5 |

SMA20 | .20 | 0.74 | ≤5.3 | 1.00 | ≤0.8 | ≤3.5 |

SMA25 | 0.25 | 0.47 | ≤8.3 | 1.50 | ≤0.8 | ≤3.5 |

SMA30 | 0.30 | 0.34 | ≤12 | 2.10 | ≤0.8 | ≤3.5 |

SMA40 | .40 | 0.18 | ≤21 | 3.50 | ≤1.0 | le;3.5 |

SMA50 | 0.50 | 0.12 | ≤33 | 5.50 | ≤1.0 | ≤3.5 |

Nitinol Muscle Wire Property Parameters

Item | One-way | Two-way |

Diameter | φ0.05~φ0.50 mm | ≥φ0.05 mm |

Surface Condition | Black Bright Finish | Black Bright Finish |

Recoverable Strain (Unloaded) | ≥2% | ≥6% |

(Rm)Tensile Strength (Rm) | ≥1200 MPa | ≥1000 MPa |

Yield Strength (Reu) | / | 100~300 MPa |

Elongation at Break (At) | ≥3% | ≥10% |

Modulus of Elasticity (E) | 5~45 GPa | / |

Nitinol Muscle Wire Working Principle

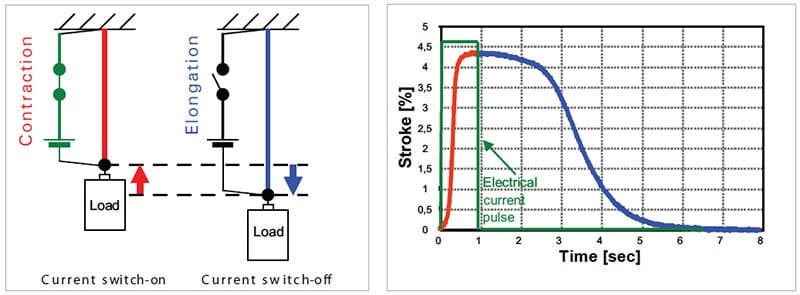

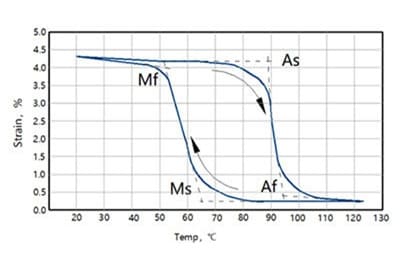

Nitinol Muscle Wire changes temperature under a certain load, and due to the phase transformation between the martensite and austenite phases, the wire undergoes shrinkage. Because the wire has a high electrical resistance, it generates heat when an electric current passes through it, making it easy to heat the material. Therefore, as shown in the diagram, by controlling the current on/off, it can be used as an actuator to drive the system.

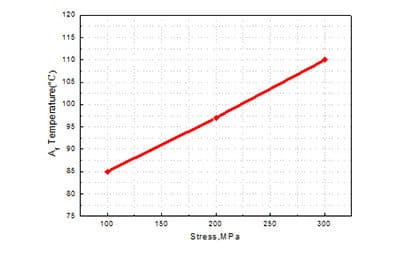

Nitinol Muscle Wire: Stress-Phase Transition Temperature (Af) Curve

- The phase transition temperature of the alloy wire varies under different stresses. As the load increases, the phase transition temperature rises.

- Compared to the unloaded condition, the phase transition temperature of the alloy wire increases by approximately 20°C at 170 MPa.

Load Stress Condition: Stress-Af Temperature Curve Unloaded Condition: Strain-Temperature Curve

Nitinol Muscle Wire Features

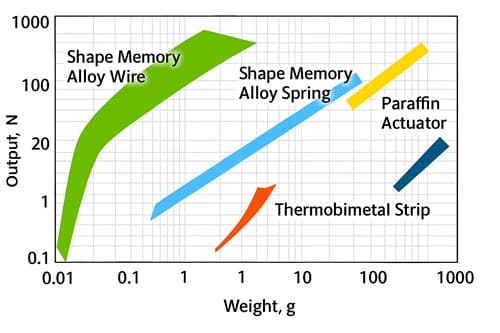

When the Nitinol muscle wire is powered or heated, it contracts along its length and generates driving stress during the contraction process, achieving the desired actuation. It features a high level of integration between the structure, sensor, and actuator. Among existing smart materials, Nitinol muscle wires have the highest energy density, high driving frequency, large output strain and stress, lightweight, and compact size. As such, they offer significant potential in lightweight design applications. Compared to actuator forms like small motors, magnetic helicoid tubes, wax actuators, and bimetallic strips, Nitinol muscle wires have distinct advantages.

- Linear and angular drive

- High specific power

- Simple structure

- Silent operation

- Precise control

- Lightweight

Nitinol Muscle Wire Applications

- Robotic actuators and bionic robots - Simulating human muscle movement for compact and silent mechanical joints.

- Aerospace applications - Deploying antennas, unfolding solar panels, or controlling valves in satellites and spacecraft.

- Medical devices - Minimally invasive surgical tools, implantable devices (e.g., vascular stents), and orthodontic wires.

- Smart textiles - Integrated into clothing for adaptive ventilation, shape memory, or temperature regulation.

- Automotive industry - Temperature-controlled valves, seat adjustments, or active aerodynamic components.

- Consumer electronics - Auto-focus in smartphone cameras, haptic feedback modules, or micro-switches.

- Safety protection - Thermal switches in fire alarms or emergency power-off devices.

- Toys and models - Actuating bionic toys (e.g., robotic insects) or controlling wings in model aircraft.

Nitinol Muscle Wire Packaging

Nitinol Muscle Wire will be packaged in custom foam inserts within sturdy wooden crates. This multi-layer protection ensures the ingots are shielded from impacts, vibrations, and environmental changes, arriving safely in optimal conditions.

Where to Buy Nitinol Muscle Wire in Bulk?

Heeger Materials Inc., a professional supplier and manufacturer of high-quality Titanium products, including Nitinol Muscle Wire, leverages extensive expertise in supply and export to offer competitive prices. We provide customized solutions to meet specific requirements, ensuring exceptional quality and customer satisfaction.

Heeger Materials Inc. was established in 2016 in Colorado, USA. We are a specialized supplier of premium-grade metals, alloys, ceramics, powders, and other materials catering to research, development, and large-scale industrial production in scientific and industrial sectors.

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy