Viewed products

-

Tungsten Copper Alloy...

Tungsten-copper alloy is a composite...

Tungsten

- Products

- Deposition Materials

- Refractory Metals

- Rare Earth Materials

- Powder

- Technical Ceramics

- Lanthanum Hexaboride (LaB6) Materials

- Pyrolytic Boron Nitride (PBN) Products

- Boron Nitride (BN) Products

- Alumina Ceramics (Al2O3)

- Aluminum Nitride (AlN) Products

- Silicon NItride (Si3N4) Ceramics

- Silicon Carbide (SiC) Ceramics

- Graphite Products

- Zirconia Ceramic

- MAX Phase Ceramic Materials

- Boron Carbide Ceramics (B4C)

- Magnesium Oxide Ceramics (MgO)

- Quartz Ceramics

- Macor Machinable Glass Ceramic

- Beryllium Oxide (BeO) Ceramics

- Piezoelectric Ceramics

- High Purity Materials

- Precious Metals

- Chemicals

- Crystals & Substrates

- Applications

- Other

Tungsten Copper Alloy | WCu Alloy | Cu-W Alloy

HTWW1133

New product

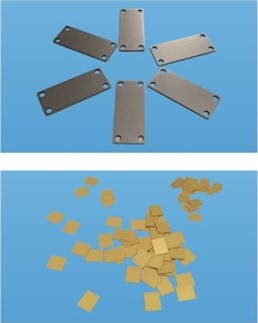

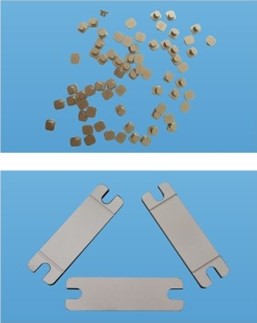

Tungsten-copper alloy is a composite material of tungsten and copper, forming a two-phase structure. It is commonly produced using powder alloy technology. Heeger Materials offers premium tungsten-copper alloy products at highly competitive prices. These alloys are available in various forms such as heat sinks, plates, and rods, and can also be customized to meet specific requirements.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Materials | Tungsten Copper Alloy |

| Purity | 99.9% - 99.99% |

| Standard | ASTM B 702 |

More info

Tungsten-copper alloy (W-Cu alloy) is a composite material that combines the high thermal conductivity benefits of copper with the low thermal expansion properties of tungsten. By adjusting the tungsten content, its thermal expansion can be tailored to match materials such as silicon (Si), aluminum oxide (Al₂O₃), and beryllium oxide (BeO). Typically, the copper content ranges from 10% to 50%. This material has high density, excellent heat dissipation, high-temperature strength, resistance to erosion, and high electrical conductivity, making it an ideal choice for high-performance applications.

WCu alloy offers the combined advantages of both tungsten and copper: it has good resistance to high temperatures and arc erosion, high strength, high density, excellent electrical and thermal conductivity, and low thermal expansion. These properties make it particularly useful for electrical contacts, where both high electrical conductivity and efficient heat dissipation are essential. Additionally, it is easy to machine, making it widely used in applications such as electrodes for resistance welding and electric spark erosion cutting machines, as well as arcing contacts and vacuum contacts in high and medium-voltage breakers or vacuum interrupters.

Tungsten Copper Alloy Specifications

- Surface: No coating, electroplated Ni, Ni-Au, or electroless Ni

- Tungsten Copper Plate: 300mm x 300mm x 0.5-50mm, customized

- Tungsten Copper Rod: 2-200mm dia. x L, customized

Tungsten Copper Alloy Composition and Properties

Composites | Nominal Composition | Density | Electrical Resistivity | Electrical conductivity | Hardness (≥) | Bending Strength | ||

Mpa | Kgf/mm2 | Mpa | Kgf/mm2 | |||||

CuW50 | 50% Copper | 11.85 | 3.2 | 54 | 1128 | 115 | --- | --- |

CuW55 | 45% Copper | 12.3 | 3.5 | 49 | 1226 | 125 | --- | --- |

CuW60 | 40% Copper | 12.75 | 3.7 | 47 | 1373 | 140 | --- | --- |

CuW65 | 35% Copper | 13.3 | 3.9 | 44 | 1520 | 155 | --- | --- |

CuW70 | 30% Copper | 13.8 | 4.1 | 42 | 1716 | 175 | 667 | 68 |

CuW75 | 25% Copper | 14.5 | 4.5 | 38 | 1912 | 195 | 706 | 72 |

CuW80 | 20% Copper | 15.15 | 5.0 | 34 | 2158 | 220 | 736 | 75 |

CuW85 | 15% Copper | 15.9 | 5.7 | 30 | 2354 | 240 | 765 | 78 |

CuW90 | 10% Copper | 16.75 | 6.5 | 27 | 2550 | 260 | 804 | 82 |

We also provide Tungsten Carbide Copper and Tungsten Carbide Silver.

Tungsten Copper Alloy Applications

Tungsten copper heat sinks are extensively utilized in a variety of applications due to their excellent thermal conductivity and durability. These applications include:

- Thermal mounting plates for effective heat dissipation.

- Chip carriers for reliable component support.

- Flanges and frames in RF and microwave packages.

- Laser diode packages and complex carriers for optoelectronic devices like amplifiers, receivers, transmitters, and tunable lasers.

Additionally, tungsten copper serves in other high-performance areas such as:

- Aerospace materials for robust performance in demanding environments.

- Vacuum contact materials and electrodes for electric discharge machining (EDM).

- Arcing contacts and vacuum contacts in high- and medium-voltage breakers or vacuum interrupters.

- Heat spreader materials and electrodes for resistance welding.

- Electronic packaging materials to ensure efficient thermal management and reliability.

Tungsten Copper Alloy Packing

Tungsten Copper alloys will be tagged and labeled externally to ensure efficient identification and quality control. Great care will be taken to avoid any damage caused during storage or transportation. They will be packed in a carton or wooden case supported with soft materials to ensure the products will not shift inside the cases.

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy