Viewed products

-

Spherical Titanium...

Spherical Titanium (Ti) powder has...

Spherical Powder

- Products

- Deposition Materials

- Refractory Metals

- Rare Earth Materials

- Powder

- Technical Ceramics

- Lanthanum Hexaboride (LaB6) Materials

- Pyrolytic Boron Nitride (PBN) Products

- Boron Nitride (BN) Products

- Alumina Ceramics (Al2O3)

- Aluminum Nitride (AlN) Products

- Silicon NItride (Si3N4) Ceramics

- Silicon Carbide (SiC) Ceramics

- Graphite Products

- Zirconia Ceramic

- MAX Phase Ceramic Materials

- Boron Carbide Ceramics (B4C)

- Magnesium Oxide Ceramics (MgO)

- Quartz Ceramics

- Macor Machinable Glass Ceramic

- Beryllium Oxide (BeO) Ceramics

- Piezoelectric Ceramics

- High Purity Materials

- Precious Metals

- Chemicals

- Crystals & Substrates

- Applications

- Other

Spherical Titanium (Ti) Powder

ME22-SP

New product

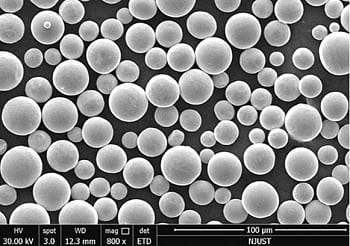

Spherical Titanium (Ti) powder has the characteristics of high purity, good sphericity, no satellite ball, excellent fluidity, large loose density, no hollow powder, and so on. Heeger Materials (HM) supplies the best Spherical Titanium (Ti) powder at high-quality and competitive prices. The particle size can be tailored according to specific requirments.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Shape | Spherical / Ball Powder |

| Particle Size | 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, customized |

| Molecular Formula | Ti |

| Purity | 99.9% |

More info

Spherical Titanium (Ti) has outstanding biocompatibility, high specific strength, and excellent mechanical properties. It is widely used in biomedical, aerospace, 3C electronics, and other fields.

Spherical Titanium (Ti) Powder Particle Size

5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. Various granularities can be customized according to customers' requirements.

Spherical Titanium (Ti) Powder Characteristics

- High purity (≥99.9%)

- Low oxygen (≤1500ppm)

- High sphericity (≥98%)

- Smooth surface, no satellite spheres, uniform particle size distribution

- Excellent flow properties (≤25.0s/50g)

- High bulk density (≥2.3g/cm3) and tap density (≥2.8g/cm3)

Spherical Titanium (Ti) Powder Applications

- Used in laser/electron beam additive manufacturing (SLM/EBM)

- Used in laser direct deposition (DLD)

- Used in powder hot isostatic pressing (HIP)

- Used in metal injection molding (MIM)

- Used in powder metallurgy (PM)

- Used in laser cladding ( LC)

- Used for 3D printing

- Used in hot isostatic pressing

- Used in injection molding

Spherical Titanium (Ti) Powder Chemical Composition

Chemical Composition - by ICP-AES | ||||||||

Element | Ti | Fe | Cr | Mo | Si | Mn | Mg | Others |

Value (%) | ≥99.9 | <0.003 | <0.001 | <0.001 | <0.02 | <0.01 | <0.01 | <0.05 |

Gas Impurities | ||||||||

Element | C | H | O | N | ||||

Value (%) | </= 0.005 | </= 0.015 | </= 0.12 | </= 0.005 | ||||

Spherical Titanium (Ti) Powder Physical Properties

Density (g/cm3) | Hall Flow Rate (s/50g) | |

Apparent Density | Tap Density | Value |

>/= 2.1 | >/= 2.8 | </= 25.0 |

Particle Size Description

- 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

- 15-45μm (D10=15~20μm,D50=25~30μm,D90=35~40μm)

- 15-53μm (D10=15~20μm,D50=25~35μm,D90=45~50μm)

- 45-75μm (D10=45~55μm,D50=55~65μm,D90=70~75μm)

- 45-105μm (D10=50~60μm,D50=75~85μm,D90=95~105μm)

- 75-150μm (D10=80~90μm,D50=110~125μm,D90=135~150μm)

Spherical Titanium (Ti) Powder SEM

Spherical Titanium (Ti) Powder Packaging

Spherical Titanium (Ti) Powder should be stored in a sealed container in a dry and cool place, and should not be exposed to air for an extended period of time. We offer vacuum-sealed packaging including 100g/bag, 500g/bag, 1kg/bag, and 25kg/drum, or we can offer customized packaging as per specific requirements.

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy

30 other products in the same category:

Download

Titanium Powder Safety

Our spherical titanium powder was passivated before shipment, but it should still be handled with care during use. Please refer to the attached detailed instructions for use. For your convenience, we have specially packaged the product in small containers. After each use, you can store the remaining powder in the small jar we provided. Seal it and keep it in a cool place.

Download (148.46k)