Viewed products

-

Nickel Based Inconel...

Inconel 718 is a...

Spherical Powder

- Products

- Deposition Materials

- Refractory Metals

- Rare Earth Materials

- Powder

- Technical Ceramics

- Lanthanum Hexaboride (LaB6) Materials

- Pyrolytic Boron Nitride (PBN) Products

- Boron Nitride (BN) Products

- Alumina Ceramics (Al2O3)

- Aluminum Nitride (AlN) Products

- Silicon NItride (Si3N4) Ceramics

- Silicon Carbide (SiC) Ceramics

- Graphite Products

- Zirconia Ceramic

- MAX Phase Ceramic Materials

- Boron Carbide Ceramics (B4C)

- Magnesium Oxide Ceramics (MgO)

- Quartz Ceramics

- Macor Machinable Glass Ceramic

- Beryllium Oxide (BeO) Ceramics

- Piezoelectric Ceramics

- High Purity Materials

- Precious Metals

- Chemicals

- Crystals & Substrates

- Applications

- Other

Nickel Based Inconel 718 Spherical Powder

SP-1298

New product

Inconel 718 is a precipitation-hardening alloy consisting of nickel, chromium, iron, niobium, and molybdenum. It offers exceptional strength, toughness, and corrosion resistance in high and low-temperature environments up to 650°C. Spherical Inconel 718 Alloy Powder is highly suitable for 3D metal printing. Heeger Materials offers top-quality Spherical Inconel 718 Powder at competitive prices.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Shape | Spherical / Ball Powder |

| Particle Size | 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, customized |

| Materials | Inconel 718 |

More info

Nickel Based: IN718 Spherical Powder

Alternative designation: 2.4668

Inconel 718 is a high-strength, corrosion-resistant nickel-chromium material used in a wide temperature range from cryogenic to high-temperature applications. The age-hardenable alloy can be readily fabricated, even into complex parts. Its welding characteristics, especially its resistance to post-weld cracking, are outstanding. The ease and economy with which IN718 can be fabricated, combined with good tensile, fatigue, creep, and rupture strength, have resulted in its use in a wide range of applications. Examples of these are components for liquid-fueled rockets, rings, casings, and various formed sheet metal parts for aircraft and land-based gas turbine engines, and cryogenic tankage. It is also used for fasteners and instrumentation parts.

Inconel 718 Spherical Powder Characteristics

Product | Chemical Composition(wt%) | ||||||||||||

HM-Inconel 718 | Fe | Ni | Nb | Mo | Cr | Al | Ti | N | Si | O | C | ||

Balance | 52.17 | 5.24 | 3.13 | 19.02 | 0.410 | 0.890 | 0.009 | 0.060 | 0.091 | 0.022 | |||

Physical Properties | |||||||||||||

Apparent Density | Tap Density | Hall Flow | |||||||||||

4.2 g/cm3 | 4.9 g/cm3 | 18 s/50g | |||||||||||

Particle Size Distribution | |||||||||||||

D10 | D50 | D90 | |||||||||||

21 μm | 33.6 μm | 53.2 μm | |||||||||||

Inconel 718 Spherical Powder Particle Size

5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Various granularities can be customized according to customer requirements)

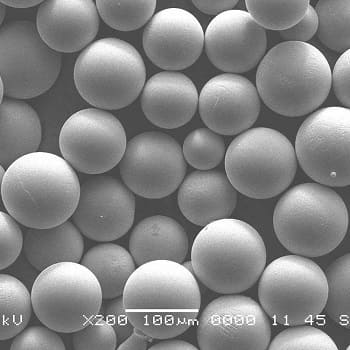

Inconel 718 Spherical Powder SEM

Inconel 718 Spherical Powder Production

We developed a unique powder production process to provide perfect spherical powders (patent pending). Any metal or alloy can be atomized according to your needs. Our processes are run with Argon as atomization gas in a dust-free production environment to guarantee maximum product quality. Any process (production, classifying, screening, packaging) can be done under Argon 5.0, so oxygen-free production can be guaranteed.

Inconel 718 Spherical Powder Screening

With various screening technologies (Cucciolini, Russel-Finex, Kellner) we can screen your powder at grain sizes from 10 to 1000 microns.

Inconel 718 Spherical Powder Classifying

With our state-of-the-art classifiers (Noll) we can provide narrow particle size distributions, produce ultrafine powders (d99<5 microns), or remove dust from your powders.

Inconel 718 Spherical Powder Packaging

Inconel 718 Spherical Powder should be stored in a sealed container in a dry and cool place, and should not be exposed to air for an extended time. We offer vacuum-sealed packaging including 100g/bag, 500g/bag, 1kg/bag, and 25kg/drum, or we can offer customized packaging as per specific requirements.

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy