Viewed products

-

Copper Clad...

Cu/MoCu/Cu is a flat-panel composite...

Molybdenum

- Products

- Deposition Materials

- Refractory Metals

- Rare Earth Materials

- Powder

- Technical Ceramics

- Lanthanum Hexaboride (LaB6) Materials

- Pyrolytic Boron Nitride (PBN) Products

- Boron Nitride (BN) Products

- Alumina Ceramics (Al2O3)

- Aluminum Nitride (AlN) Products

- Silicon NItride (Si3N4) Ceramics

- Silicon Carbide (SiC) Ceramics

- Graphite Products

- Zirconia Ceramic

- MAX Phase Ceramic Materials

- Boron Carbide Ceramics (B4C)

- Magnesium Oxide Ceramics (MgO)

- Quartz Ceramics

- Macor Machinable Glass Ceramic

- Beryllium Oxide (BeO) Ceramics

- Piezoelectric Ceramics

- High Purity Materials

- Precious Metals

- Chemicals

- Crystals & Substrates

- Applications

- Other

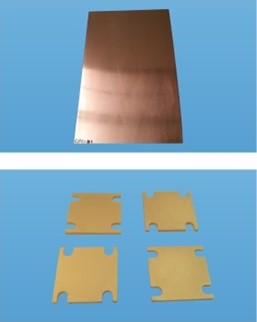

Copper Clad Molybdenum-Copper (CPC ,Cu-MoCu-Cu) Laminates Alloy

HTMO1094

New product

Cu/MoCu/Cu is a flat-panel composite material with a sandwich structure, consisting of a molybdenum-copper alloy core layer and two copper-clad layers. The typical composition of the MoCu alloy is Mo70Cu30, although Mo50Cu50 and other variations are also used. The coefficient of thermal expansion (CTE) of Cu/MoCu/Cu can be adjusted according to specific requirements.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Materials | Cu/Mo70Cu/Cu: 1/4/1, 2/3/2, 1/1/1, 2/1/2 |

More info

Cu/MoCu/Cu (CPC) is a sandwich composite similar to Cu/Mo/Cu, consisting of a Mo-Cu alloy core layer and two copper-clad layers. The thickness ratio of Cu:Mo-Cu:Cu can be adjusted accordingly. With superior thermal conductivity compared to W(Mo)-Cu and Cu/Mo/Cu, CPC offers a cost-effective solution with a higher price-to-quality ratio.

Heeger Materials provides high-quality Copper Molybdenum Copper Copper(CU/MOCU/CU) products for research and industry purposes at the most competitive prices. We can provide CU/MOCU/CU heat sinks with different grades according to your requirements.

Copper Clad Molybdenum-Copper (CPC) Properties

Grade | Density g/cm3 | Coefficient of thermal Expansion ×10-6 (20℃) | Thermal conductivity W/(M·K) | Tensile Strength (Mpa) |

CPC141 | 9.5 | 7.3 | 280(XY)/170(Z) | 380 |

CPC232 | 9.3 | 7.5/11.0/9.0 | 255 | 350 |

CPC111 | 9.2 | 9.5 | 260 | 310 |

CPC212 | 9.1 | 11.5 | 300 | 230 |

If you have an interest in other compositions of CPC like CPC300, and other contents, contact us.

Copper Clad Molybdenum-Copper (CPC) Features

- It has a higher thermal conductivity than copper/molybdenum/copper materials.

- It can be stamped into parts to reduce the cost.

- It has strong interfacial bonding, that can withstand repeated impacts at 850℃.

- It has a designable coefficient of thermal expansion and is compatible with semiconductors and ceramics.

- It is non-magnetic.

Copper Clad Molybdenum-Copper (CPC) Applications

- Thermal mounting plates

- Chip carriers for microwave components

- Flanges and frames for RF and laser diode packages, LED packages,

- BGA packages and GaAs device mounts etc.

Copper Clad Molybdenum-Copper (CPC) Packing

Copper Clad Molybdenum-Copper (CPC) is tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage caused during storage or transportation.

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy