Viewed products

-

Spherical Copper...

Spherical Copper Nickel Alloy (CuNi)...

Spherical Powder

- Products

- Deposition Materials

- Refractory Metals

- Rare Earth Materials

- Powder

- Technical Ceramics

- Lanthanum Hexaboride (LaB6) Materials

- Pyrolytic Boron Nitride (PBN) Products

- Boron Nitride (BN) Products

- Alumina Ceramics (Al2O3)

- Aluminum Nitride (AlN) Products

- Silicon NItride (Si3N4) Ceramics

- Silicon Carbide (SiC) Ceramics

- Graphite Products

- Zirconia Ceramic

- MAX Phase Ceramic Materials

- Boron Carbide Ceramics (B4C)

- Magnesium Oxide Ceramics (MgO)

- Quartz Ceramics

- Macor Machinable Glass Ceramic

- Beryllium Oxide (BeO) Ceramics

- Piezoelectric Ceramics

- High Purity Materials

- Precious Metals

- Chemicals

- Crystals & Substrates

- Applications

- Other

Spherical Copper Nickel Alloy (CuNi) Powder

SP-1776

New product

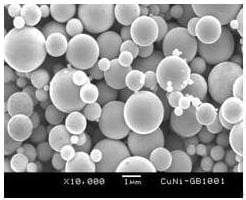

Spherical Copper Nickel Alloy (CuNi) Powder is produced by the gas atomization process, which involves the rapid solidification of the molten metal stream into small spherical particles. This method ensures high purity, homogeneity, and consistency of the final product.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Particle Size | 5-20μm, 15-45μm, 20-63μm, 45-106μm, or customized |

| Molecular Formula | CuNi |

More info

Spherical Copper Nickel Alloy (CuNi) Powder is a copper-nickel alloy containing various proportions of copper and nickel, which can also include other elements such as iron, manganese, and zinc. The addition of nickel enhances the corrosion resistance and improves the mechanical properties, making it ideal for use in harsh environments and high-stress applications.

Spherical Copper Nickel Alloy (CuNi) Powder Specifications

Product | Average Particle Size | Specific Surface Area | Tap Density | Ni content | Fe content (wt%) | Mn content (wt%) | Cu content (wt%) |

HM-CuNi-01 | 0.50 | 1.04-1.69 | ≥3.00 | 10-30 | ≤0.05 | ≤0.50 | Bal. |

HM-CuNi-02 | 1.00 | 0.50-1.00 | ≥3.50 | 10-30 | ≤0.05 | ≤0.50 | Bal. |

Note | The particle size distribution is 5-20μm, 15-45μm, 20-63μm, 45-106μm, or customized. | ||||||

Spherical Copper Nickel Alloy (CuNi) Powder Properties

- High powder sphericity

- Uniform particle size

- Good dispersibility

- High oxidation temperature

Spherical Copper Nickel Alloy (CuNi) Powder Applications

- Used in the production of electrical components such as connectors, switches, and relays.

- Used in the manufacture of automotive parts such as heat exchangers and radiators.

- Used in marine applications such as shipbuilding, seawater desalination, and offshore oil drilling.

- Used in additive manufacturing processes such as 3D printing of high-strength and corrosion-resistant parts.

Spherical Copper Nickel Alloy (CuNi) Powder Storage and Packing

Spherical Copper Nickel Alloy (CuNi) Powder should be stored in a sealed container in a dry and cool place, and should not be exposed to air for an extended period of time. We offer vacuum-sealed packaging options including 100g/bag, 500g/bag, 1kg/bag, and 25kg/drum, or we can provide customized packaging as per your specific requirements.

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy