Viewed products

-

Silicon Nitride...

Silicon Nitride (Si3N4) Powder is a...

Nitride Powder

- Products

- Deposition Materials

- Refractory Metals

- Rare Earth Materials

- Powder

- Technical Ceramics

- Lanthanum Hexaboride (LaB6) Materials

- Pyrolytic Boron Nitride (PBN) Products

- Boron Nitride (BN) Products

- Alumina Ceramics (Al2O3)

- Aluminum Nitride (AlN) Products

- Silicon NItride (Si3N4) Ceramics

- Silicon Carbide (SiC) Ceramics

- Graphite Products

- Zirconia Ceramic

- MAX Phase Ceramic Materials

- Boron Carbide Ceramics (B4C)

- Magnesium Oxide Ceramics (MgO)

- Quartz Ceramics

- Macor Machinable Glass Ceramic

- Beryllium Oxide (BeO) Ceramics

- Piezoelectric Ceramics

- High Purity Materials

- Precious Metals

- Chemicals

- Crystals & Substrates

- Applications

- Other

Silicon Nitride Powder, Si3N4, CAS 12033-89-5

HMNP-1674

New product

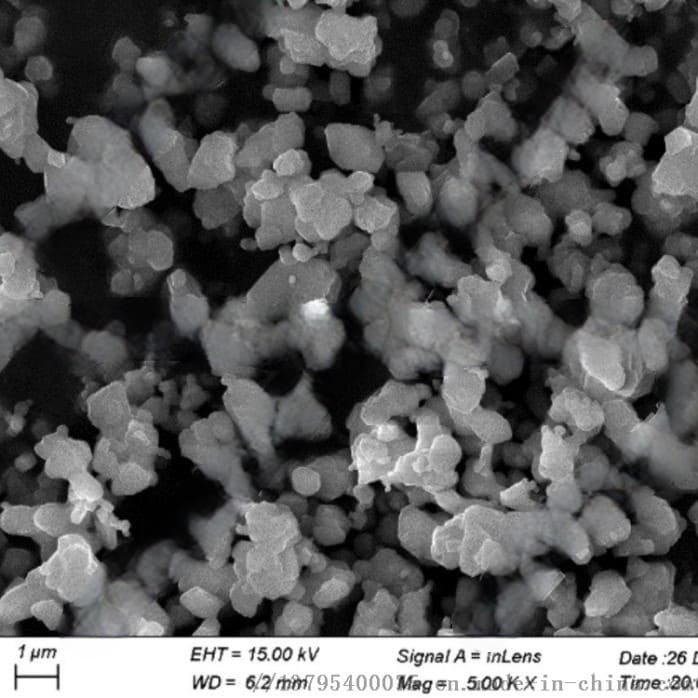

Silicon Nitride (Si3N4) Powder is a grey powder with a Moh's hardness of 8.5, it exhibits exceptional thermal stability, resistance to thermal shock, and high resistivity. Notably, it is only susceptible to corrosion by dilute hydrofluoric acid and hot sulfuric acid. Additionally, there exist other structural compositions, including Si2N, SiN, and Si2N3, which represent sub-stable phases.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Purity | 97.00% - 99.999% |

| CAS | 12033-89-5 |

More info

Silicon Nitride (Si3N4) Powder is a grey powder. Moh's hardness is 8.5. HM provides high-quality Silicon Nitride (Si3N4) Powder at a competitive price, representing a crucial structural ceramic material. This super-hard substance possesses inherent lubricity and exceptional resistance to wear and tear. Being an atomic crystal, it withstands oxidation at elevated temperatures. Moreover, it exhibits resistance to both hot and cold shocks, retaining its integrity even when subjected to heating in air to temperatures exceeding 1000°C, followed by rapid cooling and subsequent rapid heating.

- Formula: Si3N4

- Density: 3.17 g/cm³

- Refractive index: 2.016

- CAS: 12033-89-5

- Water soluble: insoluble

Silicon Nitride Powder Specifications

Product | Phase Ratio | Purity (%) | Particle D50 (μm) | Element content (%) | Impurity (ppm) | |||||

N | O | C | Si free | Fe | Al | Ca | ||||

SiN | β>50% | 99.999 | <2.5 | >38.5 | <0.8 | <0.15 | <0.3 | <5 | <3 | <3 |

SiN | β>50% | 99.999 | <0.8 | >38.0 | <2.0 | <0.2 | <1.2 | <30 | <20 | <20 |

SiN | α>70% | 99.95 | <0.8 | >38.5 | <1.0 | <0.2 | <0.5 | <50 | <200 | <50 |

SiN | α>92% | 99.50 | <2.5 | >38.5 | <2.5 | <0.2 | <0.5 | <2000 | <2000 | <500 |

SiN | α>95% | 99.00 | <5.0 | >38.0 | <2.0 | <0.2 | <0.5 | <4000 | <4000 | <1000 |

SiN | Amorphous | 97.00 | <50nm | >38.0 | <0.2 | <0.05 | N/A | <600 | <5 | <5 |

Silicon Nitride Powder Properties

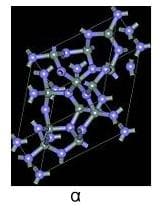

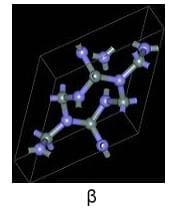

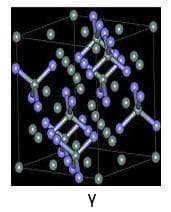

Silicon nitride is divided into α, β, and three crystal types.

- α is a low-temperature phase (1350-1450 ℃ generated), the temperature reaches 1500 ℃ above α will be converted into β, α, and β phase is often symbiotic, γ phase can only be obtained at very high temperatures and high pressure.

Silicon Nitride Powder Production Process

Silicon nitride (Si3N4) can be produced as a powder or as a film. The main methods are direct nitridation of silicon, the reaction of SiCl4 and NH3, carbothermal reduction of SiO2, and CVD. These versatile methods yield Si3N4 with high hardness, melting point, and chemical resistance for many applications.

Silicon Nitride Powder Applications

- Automotive engine parts

- High-end bearings

- High-temperature resistant parts for immersion heaters

- Human medical replacement parts

- Cutting tools

- Electronic shielding materials

- IGBT

- Solar polysilicon crucibles

Silicon nitride powder has various applications due to its high-temperature resistance, high strength, and good thermal shock resistance. Adding fluxes lowers the sintering temperature of silicon nitride ceramics to 1500-1700°C using discharge plasma sintering. Although silicon nitride ceramics have excellent properties, their high-cost limits market share. Reducing costs will expand their applications.

Silicon Nitride Powder Storage and Packing

Silicon Nitride (Si3N4) Powder should be kept sealed and stored in a cool and dry place. The vacuum packing is 100g/bag, 1kg/bag, 25 kg/drum, or as required.

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy